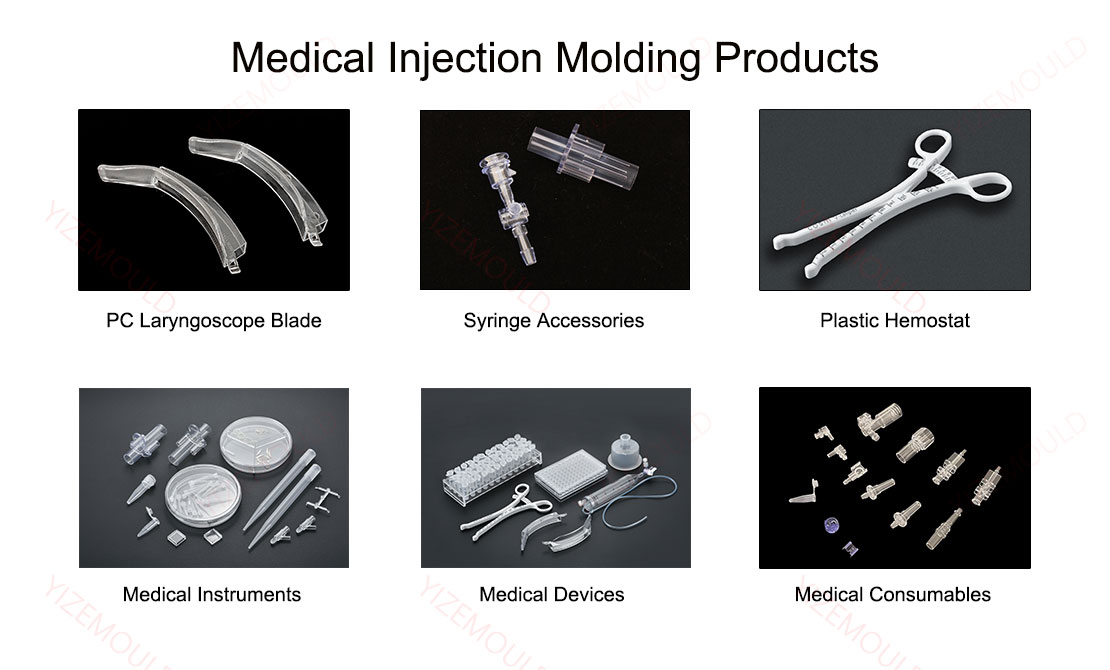

Application: medical injection molding products

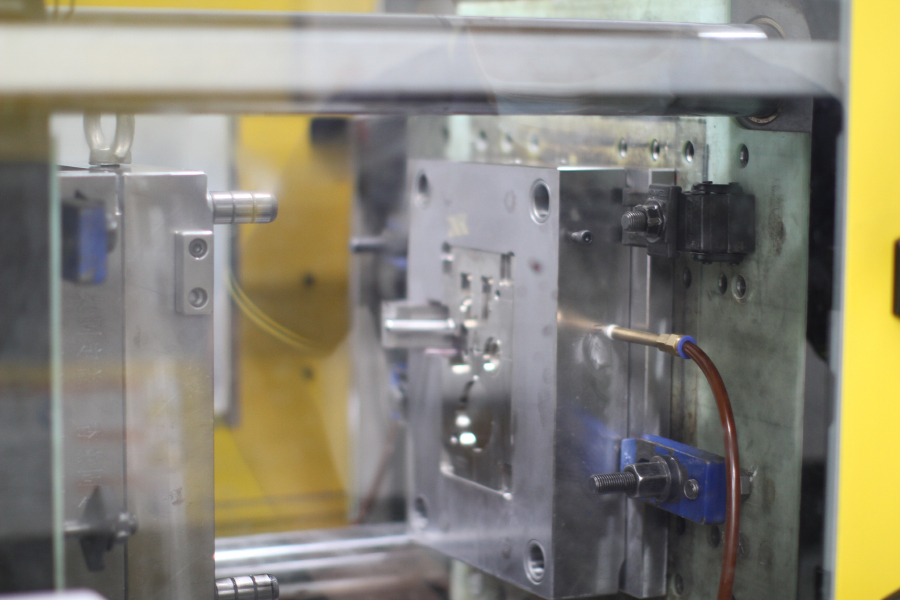

Mold Tolerance: <0.003mm

Injection Molding Tolerance: <0.02mm

The Thickness of Thin-Wall Molding: <0.2mm

Material: PC, PP, PE, PA, PPSU, PEEK, Silicone, etc...(customized)

_

Characteristics:

High precision and complex parts made for you. And We can help you make your product idea into a real thing from start to finish.

|

|

|

|

|

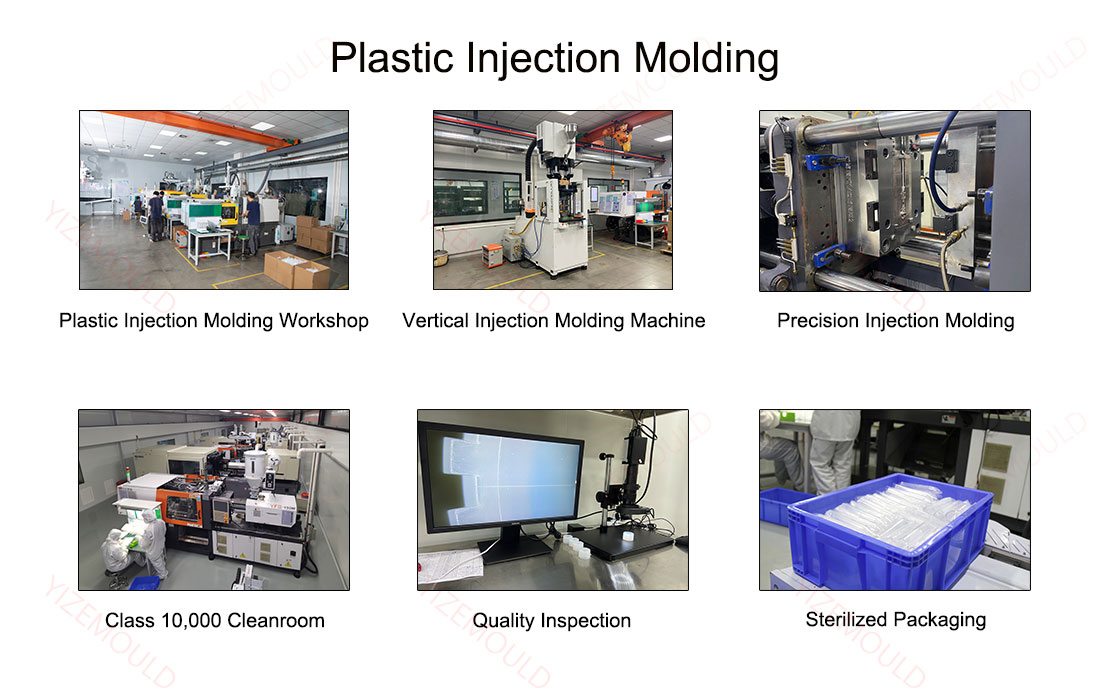

Multiple OptionsWe can provide customers with a variety of programs according to their needs. Single mold, multi-cavity mold and family mold are all available. | Complex Structure AvailableBring us the projects that others can't do! We have a professional team and advanced machine equipment, which allows us to produce complex products. | Quality assuranceWe are a trusted supplier trusted by our clients, and we are now ISO 9001 and ISO 13485 certified. |

|  |

Q: What needs to be provided for a precision mold quote?

A: Usually you need to provide 2D drawings and 3D drawings to us for faster mold quotation and manufacturing. Supported 2D drawing formats are: AI, PDF, DWG, CAD, DXF, DLG, etc. Supported formats for 3D drawings are: STP, IGS, etc.

Q: We don't have product drawings, only samples, can you process them?

A: We offer sample processing, but providing 2D or 3D drawings will allow us to understand your needs more accurately and quote faster.

Q: How about your mold making capability?

A: We have professional mold designers, and experienced technicians. There are more than 140 personnel and more than 180 sets of imported advanced mold manufacturing equipment. To see more information, you can click here.

Q: What plastics can you process for injection molding?

A: The injection molding materials we can process are: PFA, PTFE (Teflon), PA66, PEI, PVDF, PBT, POM, PPS, PEEK, LCP, PPSU, and so on.

Q: What if the processed mold does not meet the requirements?

A: Our factory strictly installs the accuracy of the drawings provided by the customer for manufacturing, but also with the customer to communicate the use of molds and precision requirements, if there is a mold does not meet the customer's requirements, if it is a problem with our manufacturing, we are responsible for arranging to redo. But if it is due to the buyer's drawings are incorrect leading to the scrapping of the product will be negotiated separately.