What is a connector?

A device that connects two active devices to send current or signals. Convex and concave surfaces can transmit information or current through contacts (also called connectors). We provide high precision connector injection Business services as manufacturer.

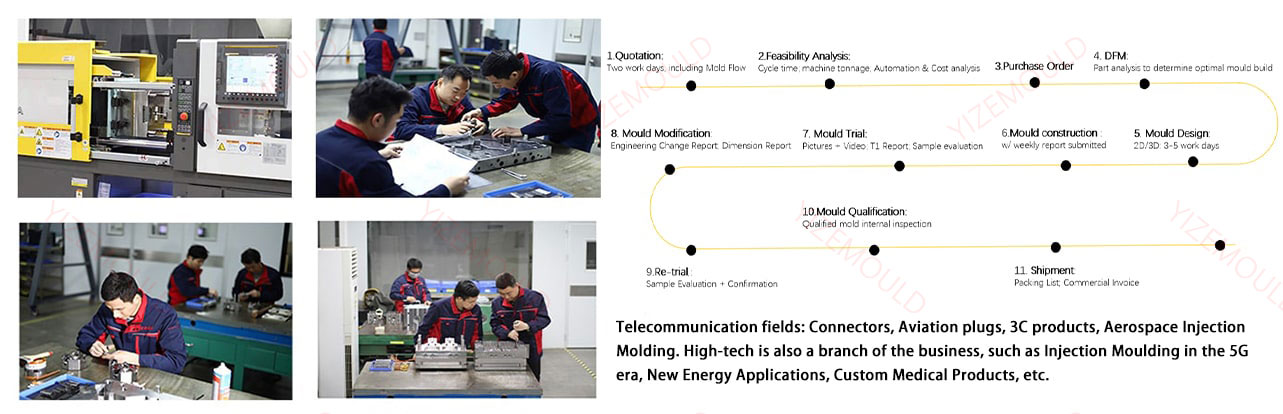

1. High precision connector injection manufacturer Design

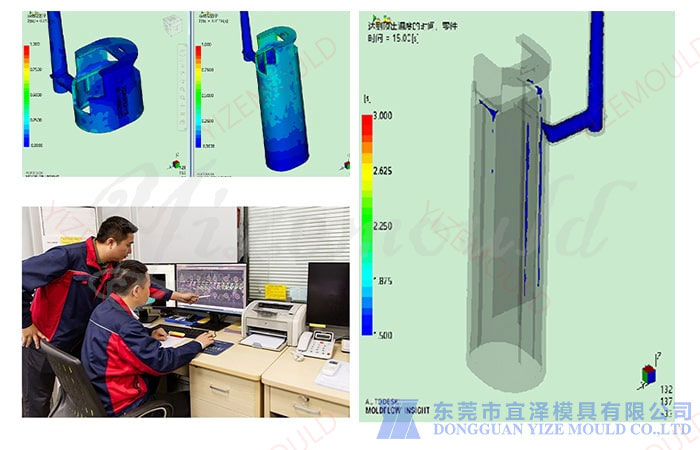

We have an experienced team of designers who can handle everything from the 3D design of molding connectors to the creation of 2D data for component processing. Through the free DFM service: make sure your manufacturing plan is ok, determine if there are any problems in the design phase, and avoid them. According to the basic principles of DFM, evaluate and minimize the manufacturing cost of the process.

2. Processing Support

After the data is generated, high precision connector injection manufacturer will arrange the machining center performs parts processing, electrode processing, EDM (wire cutting, lower die EDM), and other mold processing, and uses surface grinders and contour grinders for grinding and polishing.

3. High precision connector injection manufacturer Process

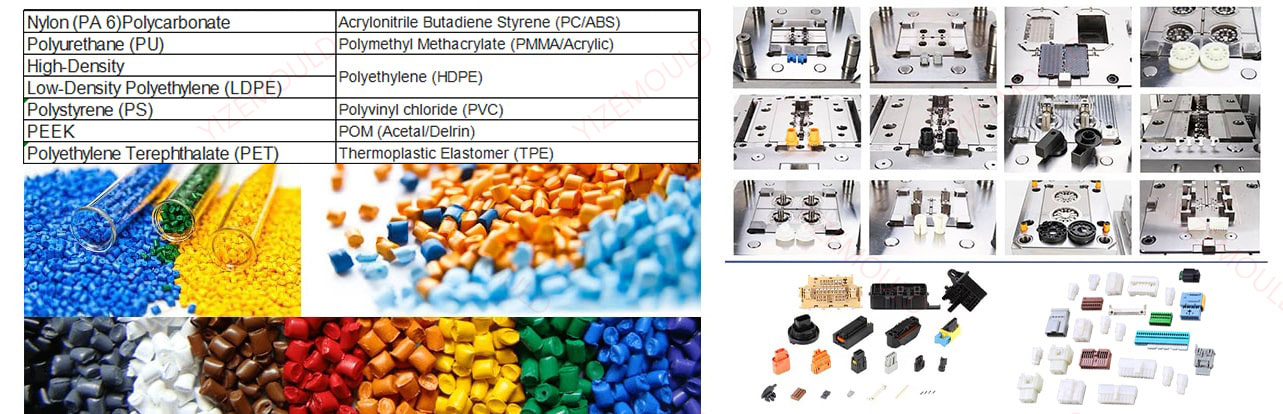

For molding connectors materials, we provide customers with the following high precision connector injection Business options:

The processed pellets are sent to a molding machine, dissolved in a liquid under pressure, poured into a mold like a syringe, and extruded. The cavity instantly cools and solidifies, and finally breaks away from injection molding.

Since the quality of the finished product varies with the high precision connector injection Business conditions, the molding technology is a subject for enterprise producers to understand. how to quickly and stably produce quality", and various experiences and technical for molding connectors know-how are extremely important.

4. High precision connector injection manufacturer Inspection Process

In recent years, due to customer requirements for miniaturization and thinning, connectors have become smaller and smaller to prevent fine dust and dirt from adhering to them. Therefore, we will continue to purchase equipment with high testing capabilities to ensure quality. We use image recognition technology to screen out defective products and set up a special inspection department to prevent defective products from entering the next process.

5. High precision connector injection manufacturer Assembly Test

After the parts are completed, try to assemble the connector mold. We have 30-100 tons of FANUC injection molding machines, which can meet the needs of different types of customers for mold trials.At the same time, High precision connector injection factory are also constantly updating equipment to ensure that our manufacturing and processing capabilities continue to improve